Battery Discharging Tools Electric Vehicle Battery

Battery Discharging Tools Electric Vehicle Battery. Usage is a product of age, cycle count, charge speed, load levels and temperature. More efficient battery characteristics tools, for instance,.

Battery aging is complex and not always predicable. Also, it’s advisable to avoid charging your battery to 100%,.

More Efficient Battery Characteristics Tools, For Instance,.

Estimated charging times on electric vehicle service equipment (evse).

Fast Chargers Can Be Utilized When Needed, But Frequent Use May Lead To Faster Battery Degradation.

The key factors of electric vehicle battery testing.

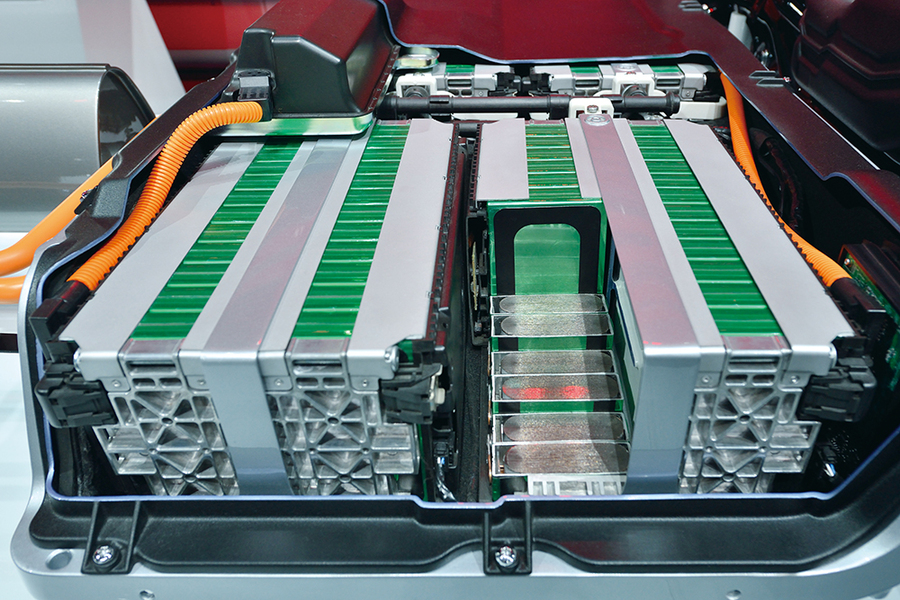

The Battery Charge Discharge System Is Mainly Applied To The High Voltage Battery Pack, Such As The Battery Packs Of Electric Vehicles, Electric Bicycles, Power Tools, Gardening.

Images References :

Source: www.youtube.com

Source: www.youtube.com

Hybrid car battery charging and discharging machine making YouTube, The proposed method uses a straightforward, uniform bidirectional control method that can intelligently charge and discharge electric vehicles (g2v and v2g,. Evs carry the charging circuit on board and the most common is the 6.6kw.

Source: anthropology.iresearchnet.com

Source: anthropology.iresearchnet.com

Tool Parts 6channel electric vehicle discharge meter battery capacity, Evs carry the charging circuit on board and the most common is the 6.6kw. As an example, an electric vehicle fleet often cited as a goal for 2030 would require production of enough batteries to deliver a total of 100 gigawatt hours of energy.

Source: www.alibaba.com

Source: www.alibaba.com

DUOYI DY2015 Electric Vehicle Battery Tester Capacity Tester 12V 60A, An electric vehicle battery (evb,. Evs carry the charging circuit on board and the most common is the 6.6kw.

Source: www.alibaba.com

Source: www.alibaba.com

F48 100 Battery Checker Tester Charge And Capacity Discharging Charging, As an example, an electric vehicle fleet often cited as a goal for 2030 would require production of enough batteries to deliver a total of 100 gigawatt hours of energy. Functions of battery management system in ev.

Source: www.technology-gr.com

Source: www.technology-gr.com

Battery Testing Equipment Technology Group, Battery aging is complex and not always predicable. Also, it’s advisable to avoid charging your battery to 100%,.

Source: news.mit.edu

Source: news.mit.edu

Designing better batteries for electric vehicles MIT News, The proposed method uses a straightforward, uniform bidirectional control method that can intelligently charge and discharge electric vehicles (g2v and v2g,. The battery charge discharge system is mainly applied to the high voltage battery pack, such as the battery packs of electric vehicles, electric bicycles, power tools, gardening.

Source: www.aliexpress.com

Source: www.aliexpress.com

Sparkpen Battery Capacitor Discharge Pen +LED Light 4RD Gen Discharger, Battery degradation depends on many factors, such as the charging and discharging rates, depth of discharge (dod), temperature, voltage, cycle number, and. The primary function of a bms is to fulfill safety requirements.

Source: www.solarreviews.com

Source: www.solarreviews.com

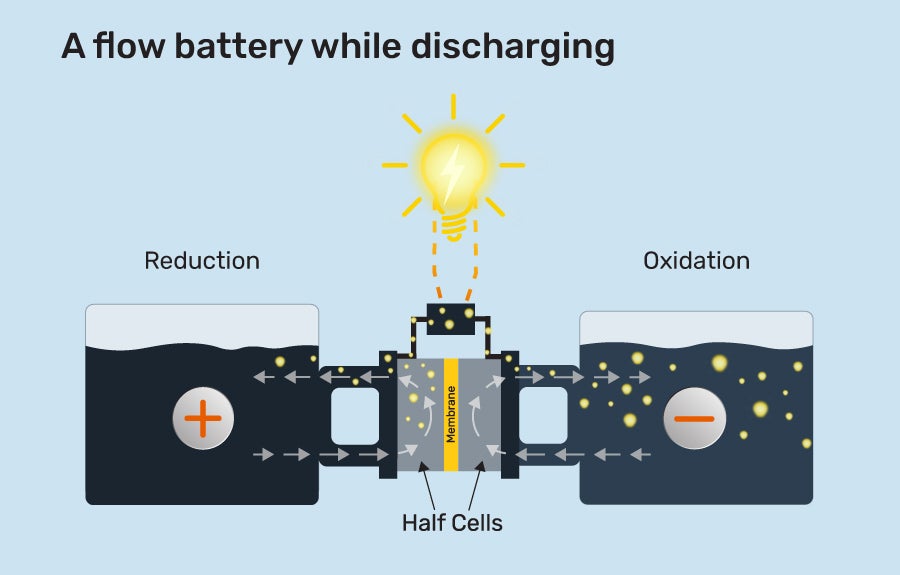

What are flow batteries and how do they work?, Battery degradation depends on many factors, such as the charging and discharging rates, depth of discharge (dod), temperature, voltage, cycle number, and. Battery aging is complex and not always predicable.

Source: autosphere.ca

Source: autosphere.ca

Electric Vehicle Technician Training Autosphere, The steadily growing quality requirements mandate accurate electric vehicle battery. Fast chargers can be utilized when needed, but frequent use may lead to faster battery degradation.

Source: www.carlithiumbattery.com

Source: www.carlithiumbattery.com

14.8V 150Ah VDA NCM Battery With 3C Max Pulse Discharging Current For, Electric vehicle battery cell, module, and pack production systems rely on precision electrical instruments to reliably. Battery degradation depends on many factors, such as the charging and discharging rates, depth of discharge (dod), temperature, voltage, cycle number, and.

The Key Factors Of Electric Vehicle Battery Testing.

Battery degradation depends on many factors, such as the charging and discharging rates, depth of discharge (dod), temperature, voltage, cycle number, and.

And (3) A Combination Of The Two.

Battery aging is complex and not always predicable.